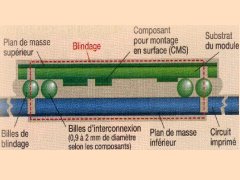

It consists in placing the SMD components and the interconnection spheres or preforms on the same substrate side. The spheres are made in an high temperature alloy and are presenting a diameter which is slightly higher than the component heights. The spheres in addition to there interconnection function, have also an interposer function to compensate the thermal mismatch between the substrate and the printed circuit board and a spacer function to allow the placement of the SMD components.Thanks to that process, NOVATEC introduces a new low cost multi-component module concept called DBIC which opens new opportunities in terms of design and miniaturisation.

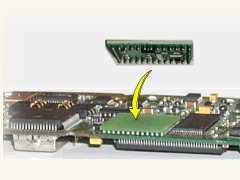

DBIC APPLICATION EXAMPLE

DBIC on a mobile phone printed circuit board.

The DBIC can be used to realise various kinds of modules such as :

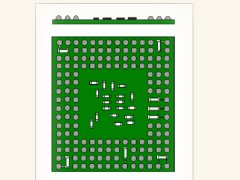

ADDITIONNAL FUNCTIONS

Use of the available surface to integrate decoupling capacitors or serial resistors directly on the BGA

SELF SHIELDED MODULES

An other original and high value added application consists in placing spheres all around the module to create an RF shield by interconnecting a top ground plane with a bottom ground plane. In that manner the module is self shielded and there is no need to use the traditional additional RF shields.